Description

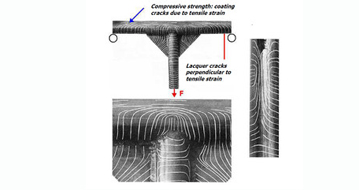

Lacquer Crack Technique – Makes Tiny Strains Visible

With the lacquer crack technique from Tiedemann smallest variable loads and expansions can be easily seen on the original functional element.* The lacquer crack was originally introduced by Maybach, 1924 and Stresscoat, 1938. As a result of using this technology you will get the main strain directions, areas of strain concentrations and the order of magnitude of the biggest main expansion. You can estimate strain below 10-4. The well-tried, ready-made „Maybach-Lacquer“ needs to be heated and painted on the heated functional element. After cooling you can put strain on the functional element. The areas of expansion become directly visible for direct evaluation or foto documentation.

The Tiedemann Lacquer Crack is made from natural ingredients, nontoxic and environmental friendly.

Technical Data

Lacquer crack

500g-container, ready for use incl. paint brush

Reviews

There are no reviews yet.